Custom 3D Printed CMM and Vision System Fixture Design

-

Custom 3D Printed CMM and Vision System Fixture Design

- Introduction

- Why 3D Printed Fixtures?

- Strength of 3D Printed Fixtures.

- What Industries Can Benefit From 3D Printed Fixtures?

- Cost Comparison

- Traditional vs. 3D Printed Fixtures by Industry

- Fixture Samples

Disclosure: Some of the links in this article may be affiliate links, which can provide compensation to me at no cost to you if you decide to purchase. This site is not intended to provide financial advice and is for entertainment only.

Custom 3D Printed CMM and Vision System Fixture Design

Introduction

In modern manufacturing and quality assurance, precision and repeatability are non-negotiable. Custom 3D printed fixtures for CMMs (Coordinate Measuring Machines) and vision systems are transforming the way parts are inspected, offering tailored solutions that enhance accuracy, reduce setup time, and increase inspection efficiency. By leveraging additive manufacturing, engineers can rapidly design and produce lightweight, cost-effective fixtures optimized for complex geometries that traditional methods struggle to accommodate. This innovative approach not only improves measurement reliability but also supports lean manufacturing practices by accelerating inspection workflows and reducing overall costs.

Why 3D Printed Fixtures?

3D printed fixtures can often be the better option because they are highly adaptable to specific applications, offering design freedom that traditional machined fixtures can’t easily achieve. Complex geometries, undercuts, or unique part profiles can be incorporated directly into the fixture design without the added cost or time of specialized tooling. This makes them especially useful for CMM and vision system inspections where secure positioning and unobstructed measurement access are critical. Additionally, 3D printing allows for lightweight yet durable structures, faster prototyping, and rapid iteration—meaning fixtures can be optimized quickly for different parts or projects. For applications with lower production volumes, frequent design changes, or intricate part shapes, 3D printed fixtures provide a cost-effective, efficient, and reliable alternative to conventional fixturing methods.

Strength of 3D Printed Fixtures.

Concerns over strength and accuracy used to be valid when 3D printing was limited to basic plastics with coarse layers and inconsistent quality—but over the past few years, there’s been a dramatic leap forward. Advanced materials like reinforced polymers, high‐performance thermoplastics, and fibre‐filled composites now deliver much greater stiffness, durability, and resistance to deformation—making fixtures much more capable under the stresses of CMM probing or holding against vibration. Accuracy has also improved: finer layer heights, tighter calibration, improved motion systems, and more sophisticated slicing algorithms have driven down tolerances into the tens of microns. Additive processes such as Multi‐Jet Fusion produce parts with near‐isotropic properties and excellent surface finish, further reducing post‐processing and aligning printed fixtures closer to machined standards. As a result, 3D printed fixtures today are far more reliable than many expect, and in many applications their performance rivals that of traditionally fabricated fixtures.

What Industries Can Benefit From 3D Printed Fixtures?

A wide range of industries can benefit from adopting 3D printed fixtures, as the technology offers flexibility, speed, and cost savings across diverse applications:

Aerospace and Defense – High-precision components often require specialized inspection setups. 3D printed fixtures allow engineers to quickly design lightweight, complex supports tailored to intricate geometries, reducing lead times for flight-critical part validation.

Automotive and Transportation – With rapid prototyping and high-volume part inspection, automakers can use 3D printed fixtures for CMM and vision systems to streamline quality checks, accommodate frequent design changes, and minimize downtime in fast-paced production environments.

Medical Device and Healthcare – From implants to surgical instruments, medical parts are typically small, complex, and require strict quality standards. 3D printed fixtures ensure accurate, repeatable positioning while allowing for rapid iteration when new product designs are introduced.

Consumer Electronics – Devices with delicate or irregular geometries benefit from custom fixtures that securely hold components during inspection without damaging surfaces, making 3D printed options ideal for fast product cycles.

Industrial Equipment and Tooling – Manufacturers of heavy machinery or precision components can leverage 3D printed fixtures to handle large, irregular parts, reducing the need for costly custom tooling while maintaining inspection accuracy.

Research and Education – Universities, R&D labs, and training facilities can take advantage of 3D printing’s cost-effectiveness to create teaching aids, prototype fixtures, or experimental setups that would otherwise be too expensive to fabricate traditionally.

In short, any industry that demands precision, frequent design updates, or cost-efficient customization can gain a competitive edge by implementing 3D printed fixture solutions.

Cost Comparison

Here’s a comparison table highlighting how traditional fixtures and 3D printed fixtures differ across various industries:

Traditional vs. 3D Printed Fixtures by Industry

Industry | Traditional Fixtures | 3D Printed Fixtures |

Aerospace & Defense | Heavy, machined from metals; long lead times; costly to adjust for complex geometries. | Lightweight composites; rapid turnaround; easily accommodates intricate part shapes. |

Automotive | Durable but time-consuming and expensive to modify for frequent design updates. | Lightweight composites; rapid turnaround; easily accommodates intricate part shapes. |

Medical Devices | Precision possible, but tooling cost is high for low-volume or custom parts. | Ideal for small, complex, low-volume parts; rapid iteration for new product designs. |

Consumer Electronics | Often too rigid or bulky for delicate, irregular shapes; risk of surface damage. | Customizable and gentle supports; precision fit for delicate assemblies. |

Industrial Equipment | Machining large, irregular fixtures is expensive and labor-intensive. | Large-format 3D printing offers affordable, lightweight fixtures for complex shapes. |

Research & Education | Traditional fixturing is often cost-prohibitive for prototyping or training purposes. | Low-cost, rapid prototyping; enables experimentation and teaching without high expense. |

Fixture Samples

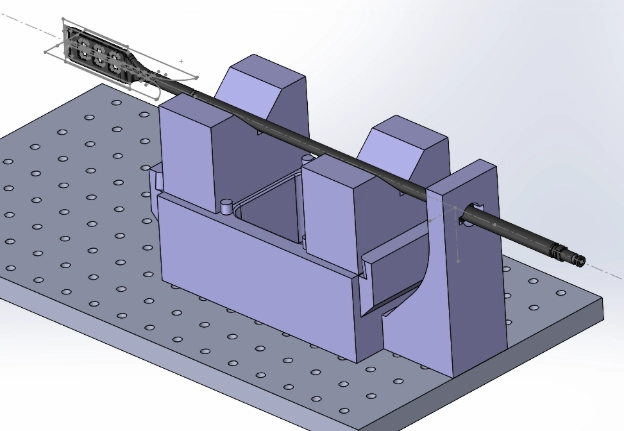

Shaft Hold-down Fixture

Click below to check out HowToCMM.com's YouTube channel

Huge selection of CMM (coordinate measuring machine) Stylii >>Click Here<<

Selection of inspection microscopes >>Click Here<<

Order your 3D printed fixtures and other items here!

Related Article: How to Report Elapsed Run Time in PC-DMIS

Related Article: How to Report a Tracefield in PC-DMIS

Related Article: How to Import Basic Script for Tracefields in PC-DMIS

-

Custom 3D Printed CMM and Vision System Fixture Design

- Introduction

- Why 3D Printed Fixtures?

- Strength of 3D Printed Fixtures.

- What Industries Can Benefit From 3D Printed Fixtures?

- Cost Comparison

- Traditional vs. 3D Printed Fixtures by Industry

- Fixture Samples

Disclosure: Some of the links in this article may be affiliate links, which can provide compensation to me at no cost to you if you decide to purchase. This site is not intended to provide financial advice and is for entertainment only.